Sun Tieying, chief physician of the Department of Respiratory and Critical Care Medicine of Beijing Hospital, once said that almost 100% of COVID-19 patients need oxygen. Therefore, oxygen inhalation is an important way to treat respiratory failure and hypoxemia caused by COVID-19. Only timely and correct oxygen inhalation can improve the prognosis of COVID-19 patients and greatly reduce mortality.

According to the latest Diagnosis and Treatment Plan of novel coronavirus Pneumonia in China (Trial Version 9), the plan provides standardized and effective oxygen treatment measures for COVID-19 patients according to their conditions, including nasal catheter, mask oxygen and oxygen therapy via oxygen high flow.

For severe patients with COVID-19, oxygen inhalation is an important means of support to help them overcome difficulties and overcome the virus. With the increase in the number of patients, the demand for oxygen has sharply increased, and how to achieve timely supply of oxygen has become a crucial part of fighting against the epidemic.

Most medical institutions adopt two oxygen supply modes, one is to use oxygen delivery and the other is to use on-site oxygen production.

Oxygen delivery method

In this approach, medical institutions act as oxygen users, and oxygen plants are responsible for producing and distributing the oxygen required by medical institutions. Although it may seem that medical institutions only need to worry about the allocation plan of oxygen usage, in the face of unexpected situations, such as a sudden increase in oxygen demand, medical institutions as users may face a shortage of supply. In the face of a public health emergency, such as the COVID-19, there may be a massive increase in oxygen use, and there may also be a lack of supply.

² 现场制氧供氧一体化解决方案

Process technology: Based on different oxygen usage scenarios of customers, process route comparison, process design, system design, pipeline design are carried out, and reasonable calculations are performed to form customized process solutions with high customer satisfaction.

Equipment technology: Through modular design, system capacity balance and operational flexibility are achieved, and interchangeability of parts and components is realized. Through equipment selection, operational flexibility and minimum energy consumption in the operating range are achieved, and high-quality components that meet the standards of oxygen technology are purchased.

Automation technology: Determine the control strategy of the entire system, establish control logic between devices, achieve overall coordination from individual equipment to oxygen production system, and establish fast and reliable automatic alarm and interlock control. The equipment operates intelligently and unmanned on site.

Operation technology: The fundamental to the safe operation of the unit is to ensure that each equipment operates within a reasonable operating range and remains in good condition at all times. Real time and accurate control can be achieved by determining the design load of the equipment and the corresponding maintenance cycle.

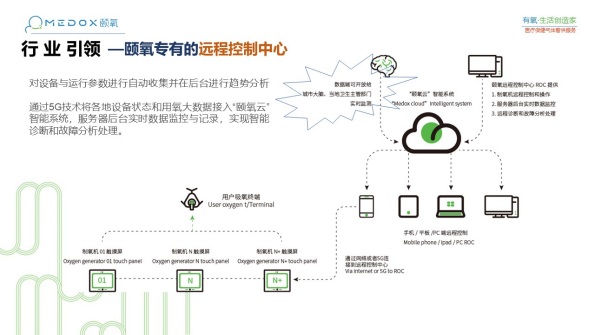

Information technology: The real-time operation big data of each device is connected to the "Oxygen Cloud" intelligent system, and the server backend performs intelligent trend analysis and fault diagnosis, which can accurately understand the behavior trajectory of the equipment and the real needs of users, providing direct basis for the safe use of oxygen and proactive expansion of hospitals, and also providing effective regulatory access for health authorities at all levels.

Response mechanism of "54321"

5-minute rapid response mechanism

4-layer technical support team

3 months of equipment inspection and maintenance

2-hour customized solution

1-Arrive at the site within 1 day

The company has established a remote control center ROC, which can monitor and analyze various process parameters of the equipment in real time, and accurately predict, dynamically intervene, and control the changes in oxygen production and supply trends through proprietary algorithms, ensuring stable operation in the optimized operation mode of oxygen production.

Through this proprietary technology guarantee and operation system, medical institutions eliminate the hassle of ordering and loading and unloading, and can achieve safe and convenient oxygen supply while balancing economy.

These medical molecular sieve oxygen production systems are equipped with intelligent control and analysis modules, which monitor gas usage data in real time to ensure that the required oxygen can be produced on site. At the same time, they can be switched to backup supply at any time during unit maintenance. Medical institutions in developed countries such as Europe and America have widely adopted on-site oxygen production methods to ensure timely oxygen supply.

The prevention and control of the epidemic still face severe challenges of complexity, difficulty, and recurrence. In the complex situation of combining epidemic prevention and control, in the absence of an epidemic, it is necessary to take precautions and reserve resources to establish a safe, convenient, and economical on-site oxygen production system. When an epidemic occurs, the contingency plan is in place, quickly switches, and emergency oxygen supply is stable, effectively responding to public health emergencies. The on-site oxygen production method may become a new trend in future oxygen supply.

Hangzhou Yioxygen Health Technology Co., Ltd. was established in 2017, adhering to the business philosophy of "creating a healthy lifestyle home" and strategically laying out the entire oxygen related field. It is an international life technology group that integrates research and development, design, construction, sales, and operation. The core team of the company is based on solid scientific research, supported by internationally leading gas production technology, and integrates cutting-edge applications in the health field. They provide innovative medical gas solutions and effect tracking and detection in medical, health, work, and life application scenarios, providing high-quality gases, complete sets of equipment, and related operational services that meet medical standards for the entire population. At present, the company has undertaken and executed various equipment projects such as oxygen and nitrogen production at home and abroad, and its business scope has rapidly expanded to international markets such as Central Asia, East Asia, Southeast Asia, and Europe.

Our integrated oxygen production and supply service

1. Safe, convenient, and reliable

On site oxygen production runs automatically, with safe and convenient operation. The oxygen output pressure is adjustable, and the quality and purity are balanced and stable. When powered on, oxygen can be produced independently, and the oxygen produced directly enters the hospital pipeline system; Within 30 minutes of startup, it can generate oxygen that meets medical standards. It has a precision monitoring system, imported accessories, and stable operation. The entire equipment operates at room temperature and low pressure, equivalent to only one bottle of oxygen reserve, with no safety hazards.

2. Economy

The company adopts two cooperation models, gas supply service and equipment service, with the aim of reducing the total long-term oxygen cost of hospitals. While ensuring equipment stability, the hospital's oxygen cost can be effectively reduced.

3. Comprehensive follow-up services

The equipment is equipped with a remote intelligent warning system, which means that professional intelligent control engineers can dynamically analyze and follow up on the operation status of the equipment in real time. If there is any maintenance or repair of the equipment, the system will provide information prompts in advance. After sales personnel will actively handle it and go to the site for inspection and maintenance to ensure the long-term stable operation of the equipment.

contact

Be the first to know about our new product launches, latest blog posts and more. Hangzhou Medoxygen Technology Co., Ltd. (hereinafter referred to as Medox) is an international life technology group and national high-tech enterprise. The company integrates research, development, pr...

Hangzhou Medoxygen Technology Co., Ltd. (hereinafter referred to as Medox) is an international life technology group and national high-tech enterprise. The company integrates research, development, pr... Any question or request?

Click below, we’ll be happy to assist. contact